The knowledge of how to make soap can be traced back to before 2800 BC. The ingredients used to make simple soaps are easily found, and early man probably discovered soap when combining ash, water, and grease.

In a survival situation, soap will allow you to maintain good hygiene. This will reduce disease and improve your mental state of mind. Making soap is a skill that is valuable both for your own household, and you can potentially sell or barter your products.

Crafting soaps is also rewarding and popular, with different designs, shapes, and scents. Creating something useful with your own hands can be very satisfying.

This article will guide you through basic steps in soap making and suggest resources if you decide to pursue the creation of your own soap. There are many good books on soap making.

If you don’t have the time or the desire to make soaps, check out our article on biodegradable soap.

Table of contents

How Soap Making Evolved – the History

Ancient civilizations used soap for cleaning purposes – utensils and dishes. These soaps were mainly made of fat or grease and ash or alkalis.

Soapmaking became popular in Europe between the 5th and 16th centuries. Europeans began using “hot processing,” where fats and lye were used to create soap. These were effective but abrasive on the skin.

“Cold processing” emerged in the 18th and 19th centuries using more refined purified alkalis. This process at lower temperatures enabled the soap to retain the benefits of ingredients and scents. This was also when presses were invented, allowing mass production.

Soapmaking became industrialized in the 20th century. Manufacturers produced detergents, liquid soaps, and other cleaning products.

During this same era, soap makers began experimenting more with fragrances, designs, and shapes. Artisanal soap making became very popular, and it still is present day.

Artisanal soapmaking has exploded with the internet. You can even purchase soap-making kits online now. Artisans around the world share their soaps and recipes. In many countries, craft fairs feature many types of soaps. Artisanal soaps is booming, creating soaps for every skin type and desire.

Soap Making 101 – Understand the Basics of Making Soap

You should have ingredients, tools, and safety gear. All three of these are critical components of soap making.

Ingredients

- Fats and oils can be animal fats, grease, or other oils such as coconut and palm oils.

- Lye, also known as sodium hydroxide, can be called caustic soda. Originally, lye was made by soaking ash in water to create a “Potash.” Today, it is often made using sodium hydroxide, which forms salts during the process.

- Water is another critical component in soapmaking.

Equipment and Safety

Using the correct equipment and practicing safe techniques is essential. Soapmaking requires hazardous chemicals, such as lye, which can burn the skin and eyes.

- Safety Gear – Safety gear is essential since you will be handling potentially dangerous chemicals. Respect the substances you are working with and use Goggles, Rubber Gloves, pants, a long-sleeved shirt, and an apron. Cover all exposed skin, including your feet! If you do not use a face mask, ensure your work area is well-ventilated.

- Equipment – Equipment includes stainless steel bowls and pans, glass measuring containers, jugs for pouring oils (stainless, glass, or Pyrex), and Small containers for essential oils and powders (don’t use plastic). Dedicate your tools to soapmaking only.

Processes Used for Making Soap

Four methods are used when making soap – Cold Process, Hot Process, Melt and Pour, and Milling. I will briefly define each one but focus on the Cold and Hot Processes in this article.

- Hot Process – This process uses heat to encourage chemical reactions. It is a great process if you want your soaps faster. It is not as suitable as the Cold Process for designs and shapes.

- Cold Process – Soaps made from scratch is how Cold Processing is touted and is also one of the most commonly used. You control all of your ingredients and create whatever you want.

- Melt and Pour – Melt and Pour bases are simple and can be used with children. They do not use lye. You melt your soap base and add the colors, scents, and designs.

- Milling – Milling combines the other processes. The soap is shredded or grated down, and heat is used to melt it. Additives such as color or scent are then added. This is another good process if you don’t want to bother with chemicals.

Cold Process

Once you have gathered the tools mentioned above and ensured you have your safety equipment, you are ready to get started! Good books are available if this is your first time using this process.

Pros

- You control the ingredients

- Glycerin, which moisturizes the skin, is produced

- You can be creative and use natural ingredients

- The soap can last for years and be stored

- Once you buy the equipment, making soap can be much less expensive than purchasing the same fancy soap.

Cons

- Working with lye can be dangerous

- The cure time is 4-6 weeks, so not fast

- The soapmaking process is one of the most complex

- Ensuring the correct pH takes equipment and practice

- It is easy to make mistakes with ingredients, which will ruin the batch

- Measure your water and lye into separate containers, handling the lye carefully.

- Carefully pour the lye into the water while stirring slowly. The solution will become hot and produce fumes, so ensure you are in a well-ventilated area or have a hood.

- Stir the water and lye until they are dissolved and cool to 100-110 degrees Fahrenheit. Use a thermometer to check the temperatures.

- Melt the oils you choose– coconut, olive, palm, in a separate container and cool to 100-110 degrees Fahrenheit.

- Pour the lye solution into the melted oils and stir with a hand blender until the mixture reaches the consistency of loose pudding. This is called reaching the “trace.”

- Add the fragrances or herbs you want to use.

- Pour the mixture into your soap mold and wrap it with plastic or parchment paper.

- Wrap the mold in towels or other insulated wraps to keep it warm.

- Allow the mold to set for up to 48 hours.

- Once the soap has set, cut it into bars, place it on racks in a well-ventilated area, and allow it to cure for 6-8 weeks. This will remove moisture, and the soap will harden.

Hot Process

The hot process allows your soap to be ready faster. It has more ingredients and design restraints than Cold Processing but it is also prevalent. As with Cold Processing, many good resources are available.

Pros

- Faster curing time

- Reduces the risk of soap heavy with lye

- Reaches trace faster

- Easier to make for beginners. Won’t seize or separate as easily

Cons

- A rougher texture and appearance

- Less time to create patterns and designs

- Lighter scents since oils evaporate during the heating process

- Easy to overcook if not careful

- Heat-sensitive ingredients, like herbs or essential oils, cannot be used.

- Measure your water and lye into separate containers, handling the lye carefully.

- Carefully pour the lye into the water while stirring slowly. The solution will become hot and produce fumes, so ensure you are in a well-ventilated area or have a hood.

- Stir the water and lye until they are dissolved and cool to 100-110 degrees Fahrenheit. Use a thermometer to check the temperatures.

- Melt the oils you choose– coconut, olive, or palm- in a crock pot until they reach 160-180 degrees Fahrenheit.

- Slowly pour the lye solution into the oils and mix until they reach 160-180 degrees Fahrenheit and Trace. Trace is the consistency of pudding. Use a hand mixer.

- Put the solution in a crock pot on low, stirring it occasionally. It is ready once the soap mixture is translucent and has no grit.

- Add the fragrances or herbs you want to use.

- Pour the mixture into your soap mold and wrap it with plastic or parchment paper.

- Wrap the mold in towels or other insulated wraps to keep it warm.

- Allow the mold to set for at least 24 hours.

- Once the soap has set, cut it into bars, place it on racks in a well-ventilated area, and allow it to cure for 1-2 weeks. This will remove moisture, and the soap will harden.

Different Ingredients to Use When Making Soap

You can get creative when making soap, and numerous ingredients exist. This makes soap-making a very satisfying project.

Oils and Fats

Oils and Fats affect the properties of soap. They determine the amount of lather, hardness, cleansing, and moisturizing.

Although animal fats rendered from beef or pork can be used, they are no longer as common. They are suitable for making hard soaps.

Vegetable and plant oils often produce milder soaps, and they are ideal because they have triglycerides. Many types of oils exist – palm, coconut, olive, avocado, etc.

Essential Oils and Fragrances

Essential oils and fragrances are commonly used. Their aromas and sensations can be tailored to specific desires. Some oils offer therapeutic properties. Below are a few common oils; there are many more.

- Lavender Oil – Soothing and relaxing

- Peppermint Oil – Invigorating

- Tea Tree Oil – Cleansing and suitable for cleaning acne-prone skin

- Eucalyptus Oil – Opens up sinuses

Colorants and Additives

Colorants are natural or synthetic. Popular natural colors include spices, natural abstracts, and activated charcoal. In some cases, as with Charcoal and Mica, they can also add texture for exfoliating.

Preservatives are also widely used for texture and moisturizing. Bees, wax, essential oils, and dairy are for the skin. Fragrance oils and clay are also commonly used.

Making Your Own Soap in the Wilderness

Knowing how to make soap in a survival situation is important, so remember these steps.

- Animal and Vegetable fats rendered from animal tallow or coconut oils, palm oils, etc.

- Get lye by leaching ashes from hardwood.

- Dissolve the lye in water and mix it with the fats. Always add the lye to the water.

- Use wood and glass containers and utensils that are not reactive.

- After pouring it into molds, allow it to cure for 24-48 hours.

- Allow the soaps to age for weeks, if not months. It will be less astringent and last longer.

Resources

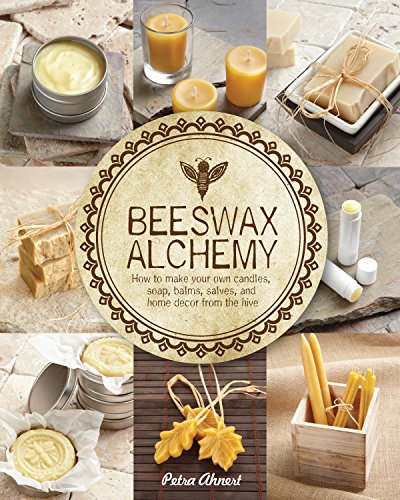

The list below is a concise list of books on making soap. There is also extensive information online.

Summary

Learning how to make soap is economical and can be rewarding work. Many artisans produce creative soaps that are highly sought after. Making soap is also complex and requires practice, so practice, practice, practice.

Knowing how to make soap in a survival situation is valuable knowledge. Cleanliness reduces disease, and soap-making is a skill that can potentially be monetized if you sell your products.

A minor correction – Lye is NOT acidic. It is the opposite of acidic in that it is “Basic” or “Alkaline” (from where the shortened version of the name is derived). While many of the results of exposure are similar to acids, it is incorrect to say that lye is acidic. Also, alkaline burns damage bodily tissues differently than acid burns. Acid will essentially create a barrier that prevents further penetration of the chemical while alkaline substances tend to wick the agent further into the skin. It’s important to know which way the pH goes to help with treatment.

My error – I knew better. Thanks for the heads up!