Probably the first thing that comes to mind when you hear of biofuels is that it is a cheap fuel, made using homemade equipment and recycled materials that will end up messing with your engine and should not be considered for use at all. But did you know that we have been using biofuels for ages?

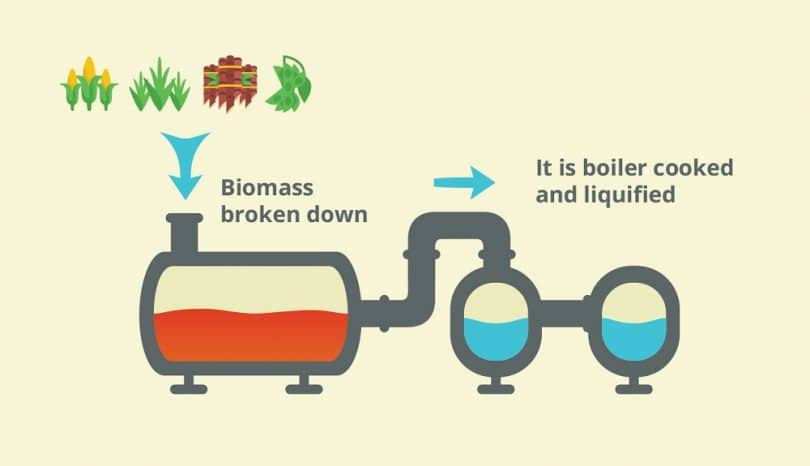

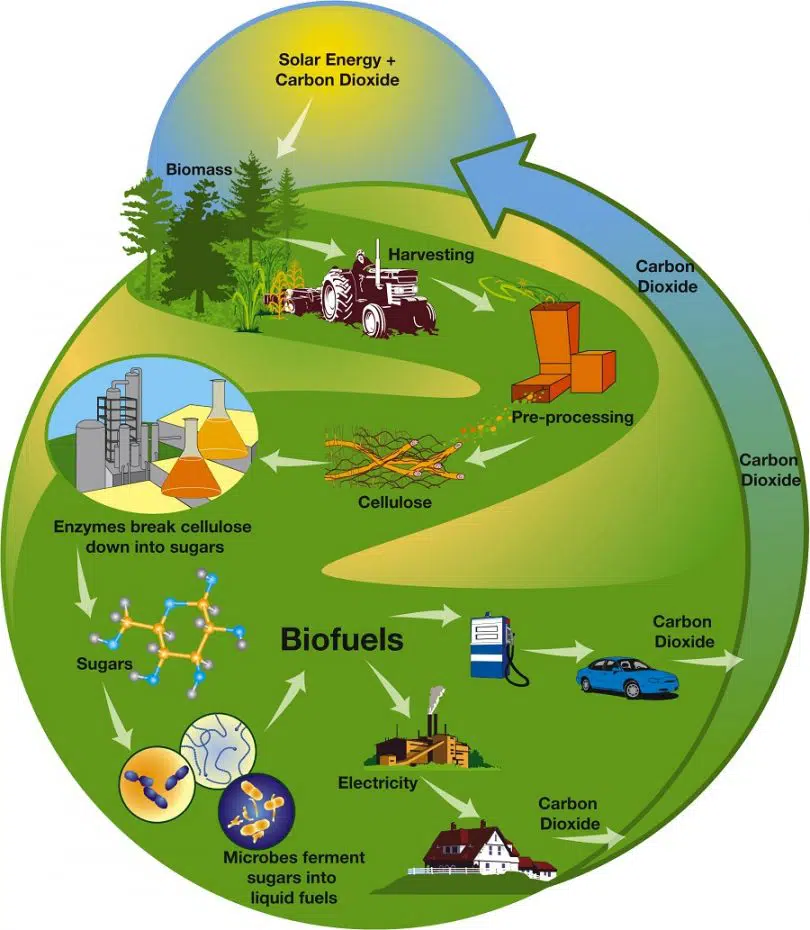

[the_ad_placement id=”in-text-1-type-r”]Biofuel is a type of fuel that is derived directly from natural resources and is produced through unadulterated biological processes like anaerobic digestion and mulching. As compared to fossil fuels where petroleum and coal are created using natural geological processes and is not sustainable and takes a long period of time before its innate energy can be fully harnessed, biofuels are renewable and it does not take millions of years before they can be used as an energy source.

Having been processed biologically, biofuels can come in all states: solid, liquid and gas. Possibly the very first biofuel that humanity ever used is wood and the by-product of burning it, charcoal. As civilization progress, man was able to discover other materials that can also provide fuel like whale oil, biogas, various plant-based oils and the like. For a period of time, biofuels were the main source of energy until the discovery of fossil fuels.

The discovery of fossil fuels as an energy source brought about rapid development of infrastructure and technology but the dependence on coal and petroleum does not mean that biofuels were completely forgotten, using modern chemistry methods, biofuels have been enhanced and further improved.

Types of biofuels

Biofuels come in all forms and their use is dependent on their consistency and ability to burn and produce energy. The most common types of biofuels are:

- Ethanol – this is the most common type of biofuels and is derived through natural fermentation using enzymes on sugars and starches. Ethanol can be used to replace traditional fuels but the drawback is that it has a lower energy density and thus would need more volume to produce the same amount of energy as that of diesel and gasoline. It can be mixed with other types of petroleum to produce a more environment friendly fuel.

- Methanol – this is mainly produced from natural gas through anaerobic metabolism. This type of biofuels is highly toxic though and is not fit for consumption as of now. Further research is being conducted to lessen its toxicity.

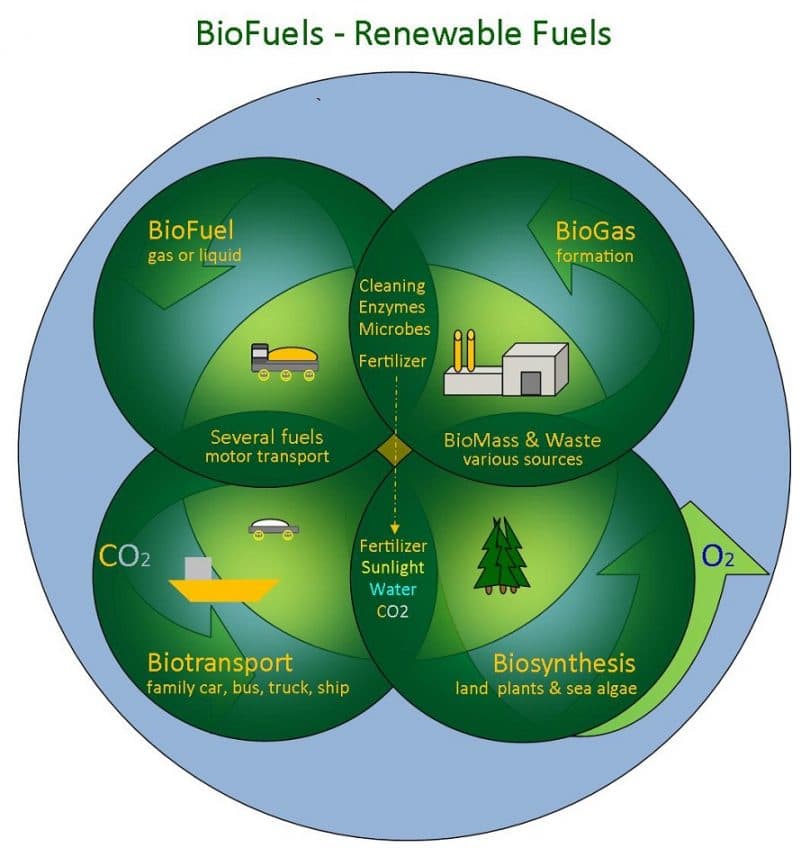

- Biogas – produced through anaerobic digestion of organic material like fecal matter, farm and food wastes, biogas is a renewable energy source and has a very low carbon footprint as compared with other kinds of biofuels. This can come in gas and solid states with varying applications.

- Bioethers – having a relatively low energy density, bioethers cannot be used as a fuel on its own but it has been widely used as an enhancer for petroleum as it has a lower impact on the environment that lead-based enhancers.

- Vegetable Oil – commonly used for frying, vegetable oil in some stages of its life cycle can directly replace diesel as fuel for engines. More and more people are now reprocessing used vegetable oil to create a less viscous fuel that they place and run their cars with.

- Biodiesel – this is produced from a wide variety of organic materials like vegetable oil, seeds even algae. Biodiesels have a much lower emission than mineral based fuels and is the most common biofuels in Europe.

- Butanol – this is a naturally produced alcohol and has a high energy gain if processed properly.

Biofuels uses & benefits

Recent improvements in the make-up and production of biofuels have enabled it to be part of regular consumption, and unbeknownst to some, biofuels, like ethanol, are added to the chemical mixture made for gasoline and diesel. Biofuels help reduce the contaminants that result from combusting fossil based fuels.

Some of the modern uses for biofuels include:

Transportation – Recent development in biofuel technology has provided society with a renewable source of fuel for transportation. Biodiesels, ethanol and vegetable oil is currently being used in several countries to replace traditional fuel. Current trends have allowed biofuels to be mixed with mineral based fuels to produce a more efficient compound that has a lower emission rating and helps protect the engine as well.

Power – As with combustion engines, power plants also require petroleum based fuels to make it run but biofuels are slowly reducing our dependence on mineral based products. Biogas, for example, are being harnessed by farms and other agriculture-based businesses to power their facilities providing them a way to dispose of their waste materials without adding to the waste management problems the world is experiencing right now.

Heat – Heating is an essential need to any home located north of the equator. As with engines, traditional heaters require fuel to run and heat a home and biofuels have almost taken over this particular field due to their lower cost. Biologically processed gas like butanol and propanol are often used in heating systems. Some types of biofuels have also been used for cooking.

Discussing benefits, here are some of the most popular ones:

Sustainable – The current drive to look for and use renewable energy sources have placed the spotlight on biofuels as, unlike fossil fuel, they do not take a long time to be produced and as long as their raw materials are available they can always be made again and again.

The variety of possible raw material sources makes biofuels renewable and sustainable and plant based materials can be planted again and again depending on the need, plants can be swapped for others if the demand is low and plant based materials not only provide biofuel materials but they also help clean the air too through photosynthesis.

Cost effective – Mineral based fuels require transportation from the mining site to the processing plant and from the processing plant to the gas stations. This does not include costs related to research and processing of petroleum from crude oil. Biofuels can be processed in the same area wherein they are sourced so it does cut down on operational and transportation costs. Biogas can be harnessed from the same farm and biodiesel plants can be constructed near raw material plantations.

Biofuels are also cleaner than traditional fuels and this means that they can preserve your engine better, lessening maintenance costs for your vehicles. Its adaptability to any type of engine also adds to the cost efficiency of biofuels.

Reduced dependence on fossil fuels – As you may know, fossil fuels are extracted from the fossilized remains of plants and animals and although it is claimed that the planet has a great reserve of fossil fuels yet to be mined, this is not infinite and will dry up sooner if the demand does not decrease drastically. Adding biologically processed fuels into the mix gives consumers a choice and lessens society’s dependence on petroleum.

Environment friendly – It is widely accepted that biofuels are cleaner than mineral based fuels but they actually process the same chemical compound, hydrocarbon, and thus produce almost the same amount of carbon emissions.

The advantage of biofuels lies in how it is made and transported. Sustainable sources mean that the same plot of land can be used again and again to produce the same amount of raw material whereas an area mined for fossil fuels can no longer be used for anything else. Topsoil is preserved in biofuel production, meaning it can be used for agriculture as needed.

See also: How to Make Gel Fuel: Staying Warm in The Wild

As biofuels can be sourced and processed in the same general area, transportation is no longer needed, thus reducing the carbon emissions made during transport. This also lessens the chances of the fuel being spilled into the surrounding areas accidentally. Spills from biofuels are also easier to clean and have a significantly lower impact to the ecosystem.

[the_ad_placement id=”in-text-2-type-r”]Biofuel manufacturing also takes advantage of plants that are not usually used for human consumption, furthering research efforts to look for other plant based materials that can be used for biofuels. A nifty side effect is that other uses (medicinal or otherwise) are also discovered expanding the current knowledge about Earth’s ecology.

Brewing your own fuel

One great advantage of biofuels is that you can actually make them right at the comfort of your own home, well, maybe outside your house, a few hundred feet if possible. The materials and equipment that you would need are readily available in your local shops, if not you can always find and order them online. The easiest biofuel to produce and set-up with minimal equipment is the biodiesel.

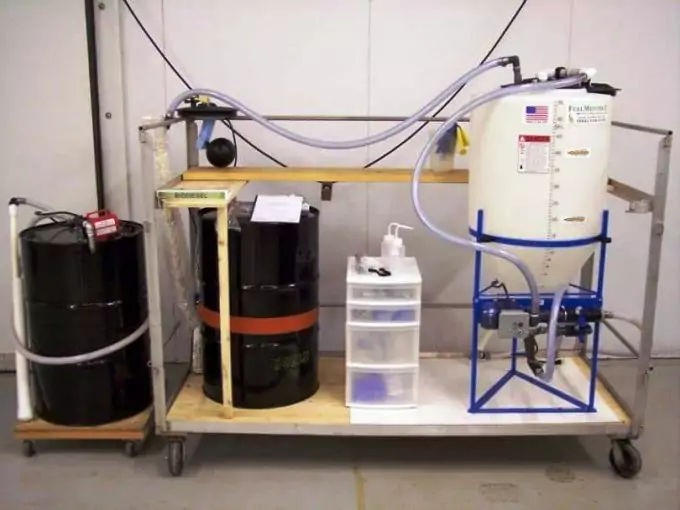

Image credit: makingbiofuel.blogspot.mk

As discussed earlier, biodiesels are created using organic material mixed with a catalyst and enzymes. Home brewed biodiesel is the product of vegetable oil reacting with methanol and another catalytic compound but it’s not as simple as it sounds. You would need the proper tools in order for your biodiesel to be usable.

Equipment needed

The first and foremost thing you would need to create biodiesel is a biodiesel reactor which you can order online or, if you want to be self-sustaining, you can build one. For the biodiesel reactor, you can use an old tank style water heater, a pump and some plumbing valves, pipes and couplings. In order for the reactor to be secured, you will also need some adjustable straps and some power cords to power everything.

Assemble the reactor by connecting the pipes from the tank to the heater and ensure that all joints and couplings are tightly secured. You can then test the system for leaks and other problem areas. This step is necessary as it will prevent any mishaps when you are handling the actual biodiesel process already.

Image credit: instructables.com

For smaller batches of biodiesel, you can opt to use empty 4-liter mineral water or juice bottles, a small stove, an old working blender and some old pots instead of creating or purchasing a biodiesel reactor.

Some other equipment that you would need is weighing scales and other measuring implements. Crafting your own biodiesel requires exact science and ingredients should be measured and weighed carefully.

For your own safety, make sure you have several pairs of rubber gloves and safety goggles at hand. You will be handling chemicals that might cause an adverse reaction when not handled with care.

Materials needed

The materials you would need to make your own biodiesel are vegetable oil as your main ingredient, methanol as the reacting compound and caustic soda or potassium hydroxide as the catalyst. Vegetable oil can be the straight from the grocery kind but save some money and use spent vegetable oil. You can network with local restaurants and get their used oil, for free or for a reasonable price.

Methanol is an industrial alcohol based solvent and is sometimes used as antifreeze so extreme caution is needed when handling this chemical. Caustic Soda can be sourced from supermarkets and the one you should purchase should be at least 99% pure. Always check the label to ensure that you are getting the right chemical. If caustic soda is not available, 100% lye can be used.

A word of warning though, you may be asked by suppliers for a proof of identification and a statement of purpose. Why? The chemicals just listed are also use for the manufacture of illegal substances and, especially if you’re buying in bulk, it will definitely arouse suspicion from authorities.

Precautions

Before you start processing your own biodiesel, take the following precautions to prevent any injury or untoward accidents from happening. Remember that the chemicals that you will be handling are flammable and toxic.

- Wear the right clothes. When handling dangerous chemicals, it is advised that you wear long sleeved clothing, denim or pants made of thick material, chemist’s gloves, aprons and eye protection.

- Have running water on standby so you can easily wash off any chemical spills.

- Make sure that no children or pets are around to accidentally handle your preparations.

- Have a gas mask ready just in case harmful vapors are diffused as a result of the mixing.

Procedures

The procedures detailed below are for smaller batches of biodiesel which you can do in your kitchen or garage.

- Prepare your work area by clearing up any mess and ensuring that the area is well ventilated to avoid suffocation.

- Measure about 5 grams of lye and mix it with 220 ml of methanol. Place the mixture in a glass beaker or jar and stir until the lye or caustic soda is dissolved. You can use a blender on this step but make sure that you never use the blender for any other purpose again.

- The resulting solution is meth oxide, which is a highly potent compound. Set this aside.

- Measure about 1 liter of vegetable oil and pour it into a pan. If you are using used cooking oil, make sure to filter it first before pouring it into the pan.

- Heat the oil up to 130 degrees. This would make any residual water boil and turn into steam, leaving you with 100% oil. Used vegetable oil will take longer than “fresh” vegetable oil as it has gone through its first original frying and liquid from whatever was cooked in it will have mixed with the used oil.

- Once heated, pour the oil into a 4-liter juice bottle and mix the meth oxide solution in.

- Carefully seal the bottle and give the bottle a vigorous shake (about 5 minutes) to ensure consistency. Set aside.

- The liquid will settle after a few hours. The result will have the biodiesel on top and glycerin at the bottom. Leave the mixture alone for about 24 hours.

- There will be a dramatic change in color and the division between the glycerin and the biodiesel will be visible at this point.

- Pour the biodiesel into another 4-liter bottle and make sure that none of the glycerin will pour into the new container.

- After transferring the biodiesel, you will need to wash and dry the mixture. This is done by adding warm distilled water into the biodiesel and slowly mixes the two together.

- The solution will be soapy and you need to filter the soapy part out by turning the bottle over and pouring the soapy part out. You will need to repeat the process two to three times until all the soapy liquid has been poured out.

- After washing the solution, you can leave the biodiesel to dry out. You need to make sure that the bottle is uncapped and is in a cool, dry place. It will take a couple of days before it is completely dry and becomes ready for use.

Video link:

When using a biodiesel reactor, the procedure varies a little as the reactor will do most of the work for you. You just need to filter the used vegetable oil before pouring it into your collection tank which will then feed the oil into the biodiesel processor.

Video link:

Brew it and gas up!

[the_ad_placement id=”in-text-3-type-r”]The call for using renewable energy has never been greater and recycling used vegetable oil helps in answering this call. You not only help dispose of otherwise wasted material but you also create a sustainable source of energy for daily consumption.

For more information see our article on alternative sources of energy for the home to give you other options.

I must say, this is a very interesting read. I have heard of people making fuels out of used materials but I never thought it would be this easy. Now if only I can get my hands on some used water heaters.

People everywhere are quite creative and this is how we end up with so many interesting ideas.

I have been reading about this and consensus is biodiesel is also a good alternative for traditional petroleum diesel. No retrofits are necessary for use in existing oil heating systems and diesel powered combustion engine if your car was made after 1993. [Cars made before 1993 will need to have their rubber fuel lines replaced]. Biodiesels are a good way for farmers to save money by making their own biodiesel for use in tractor engines. However, they should also expect to change fuel filters after the first several hours of initial use of biodiesel.

It is beyond any reasonable doubt that biofuel is an affordable alternative that we have been using for ages. If I were you, I wouldn’t pass an opportunity to make some.